The Rise of SAIF: Redefining Manufacturing in the Kingdom

In the industrial corridors of Jubail, Yanbu, and the new high-tech zones of Riyadh, a new acronym is taking shape. It is not just a buzzword. It is the target destination for the entire National Industrial Development and Logistics Program (NIDLP). We call it SAIF: The Smart Artificial Intelligence Factory.

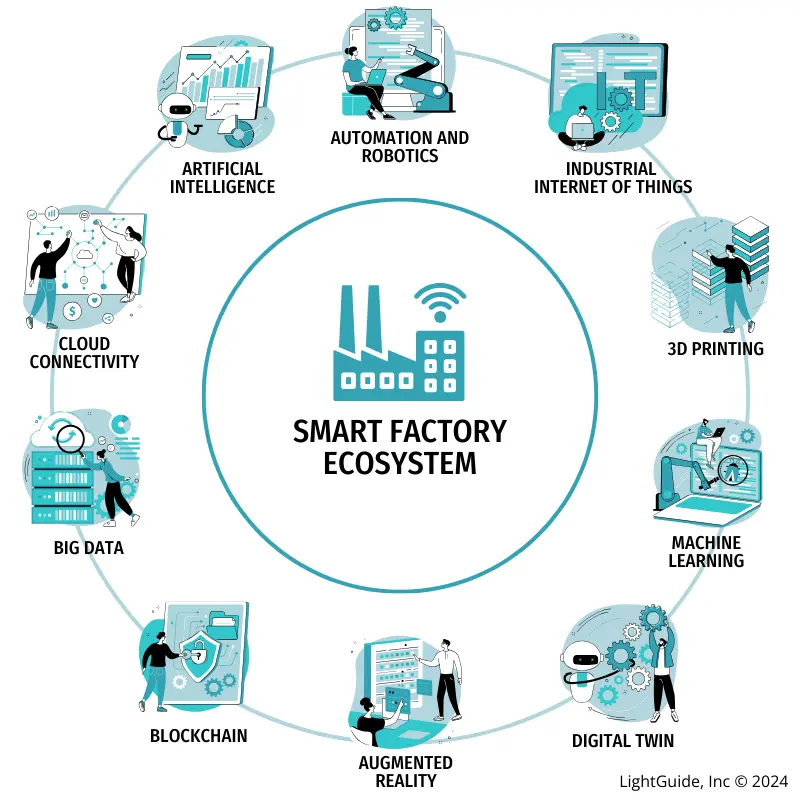

This concept goes beyond simple automation. A traditional automated factory follows pre-programmed rules. A SAIF does not just follow rules; it writes them. It uses the Industrial Internet of Things (IIoT) to sense its environment and Artificial Intelligence to make decisions without human intervention. As Saudi Arabia races to transform 4,000 factories into advanced manufacturing hubs under the Future Factories Program, understanding the anatomy of a SAIF is critical for every CEO and plant manager in the Kingdom.

This extensive guide explores the convergence of IIoT and AI. We will dissect the infrastructure required to build a SAIF, the role of the SIRI (Smart Industry Readiness Index), and how the massive 2025 investments by PIF and NVIDIA are creating the digital backbone for this industrial revolution.

The Core Pillars of a SAIF Architecture

Building a Smart Artificial Intelligence Factory is like building a living organism. It needs a nervous system (IIoT), a brain (AI), and a circulatory system (Data). Here is how these layers stack up in the Saudi context.

1. The Nervous System: Ubiquitous Sensing (IIoT)

In a standard factory, sensors trigger alarms. In a SAIF, sensors generate training data. Every vibration,

temperature spike, and power fluctuation is recorded.

The Difference: A legacy system stops the machine when it overheats. A SAIF system notices the

temperature rising 0.1% faster than usual and slows down the motor speed by 5% to cool it down while

maintaining production.

2. The Brain: Sovereign AI and Edge Computing

With the launch of the SDAIA "Sovereign AI" initiatives, Saudi factories are moving away

from public clouds for critical control. Decisions happen at the "Edge."

Application: An Edge AI controller at a bottling plant in Jeddah watches the conveyor belt. It

spots a bottle cap that is slightly skewed. Instead of rejecting it later, it signals the capper machine to

adjust its torque for the next cycle. This is self-correction in real-time.

3. The Backbone: 5G and Private Networks

You cannot run a SAIF on Wi-Fi. The latency is too high. Saudi Arabia's leadership in 5G deployment allows factories to build private 5G networks. This enables mobile robots (AMRs) to swarm and coordinate logistics without crashing into each other.

The "Future Factories" Program and SIRI

The Ministry of Industry and Mineral Resources has set a clear benchmark. To be recognized as a globally competitive facility, you must score high on the Smart Industry Readiness Index (SIRI).

Why SIRI Matters for Your Factory

SIRI is not just a badge of honor. It opens doors. Factories that score high on digital maturity get priority access to SIDF (Saudi Industrial Development Fund) loans and grants. Transforming into a SAIF is the fastest way to improve your SIRI score.

The assessment looks for "Connectivity" and "Intelligence." Installing a robust IIoT sensor network from a provider like IIoT-Bay is often the first step to moving from the "Band 1" (Beginner) to "Band 3" (Advanced) category.

The Role of Digital Twins in SAIF

A true Smart AI Factory exists in two places at once: the physical world and the digital world. This is the concept of the Digital Twin.

Simulation Before Execution

Imagine you want to increase the line speed by 15% in your Dammam plant. In the past, you would try it and hope nothing breaks. In a SAIF, you run the scenario in the Digital Twin first. The AI predicts that bearing #4 will overheat at that speed. You replace the bearing before you increase the speed.

The NVIDIA Omniverse Connection

With the recent partnerships between KSA and global tech giants, platforms like NVIDIA Omniverse are becoming the standard for building these industrial metaverses. They allow operators in Riyadh to walk virtually through a factory in Jizan, inspecting machinery using VR headsets.

Case Study: The Autonomous Petrochemical Plant

Let’s look at a theoretical implementation in Jubail Industrial City to understand the SAIF concept in action.

The Problem

A petrochemical reactor requires precise temperature control. A variance of 2 degrees can degrade the product quality. Human operators manually adjust valves based on experience.

The SAIF Solution

Step 1: Thousands of IIoT sensors are retrofitted to valves, pipes, and heat exchangers.

Step 2: Historical data is fed into a Deep Reinforcement Learning model. The AI learns

the complex physics of the reactor.

Step 3: The AI is given control of the valves. It makes micro-adjustments every second,

reacting to changes in ambient humidity and feedstock quality that a human would never notice.

The Result

Yield increases by 4%. Energy consumption drops by 10%. The plant operates in a state of continuous "Perfect Optimization."

The Human Element: From Operator to Supervisor

There is a fear that AI will replace jobs. In the Saudi context, the goal is job elevation. Vision 2030 aims to reduce reliance on low-skilled expat labor and create high-value jobs for Saudi nationals.

In a SAIF, the Saudi worker is not turning a wrench or watching a monotonous screen. They are "AI Trainers" and "Robot Fleet Managers." They interpret the insights generated by the IIoT system and make strategic decisions. The factory becomes a high-tech environment that attracts top engineering talent from universities like KFUPM and KAUST.

Overcoming the "Brownfield" Challenge

Building a SAIF from scratch (Greenfield) in NEOM is easy. Turning a 30-year-old factory in Riyadh's Second Industrial City into a SAIF (Brownfield) is hard.

The Retrofit Strategy

You do not need to throw away old machines. You give them a voice.

Overlay Sensors: Stick wireless vibration sensors on old motors.

Edge Gateways: Use protocol converters to pull data from legacy PLCs (like old Siemens

S7-300s) and send it to the AI cloud.

Unified Namespace: Create a single data structure where data from the old machine looks

exactly like data from a new robot.

This is where IIoT-Bay's expertise shines. We specialize in the "Digital Retrofit," bridging the gap between 1990s hardware and 2030 intelligence.

The Road Ahead: 2026-2030

The pace of change is accelerating. By 2026, we expect to see the first "Dark Factories" in KSA—facilities that can run entirely without human presence for 24 to 48 hours.

The convergence of Generative AI (like ChatGPT for machines) will allow operators to talk to their factories. You will be able to ask your dashboard: "Why was production slow between 2 AM and 4 AM?" and the SAIF will answer: "The raw material feed had higher moisture content, so I slowed the dryer down to compensate."

Conclusion: Join the Industrial Revolution

The concept of SAIF is the logical conclusion of the Industry 4.0 journey. It transforms manufacturing from a brute-force effort into a refined, intelligent science. For Saudi Arabia, it is the key to economic diversification and industrial sovereignty.

The technology is here. The government incentives are here. The only missing piece is the decision to start. Will your factory be a relic of the past, or will it be a Smart Artificial Intelligence Factory of the future?

Build Your Intelligence Layer Today

The journey to SAIF starts with a single sensor. Partner with IIoT-Bay to design the IIoT infrastructure that will feed your AI. Let's build the future of Saudi industry together.