The 50°C Challenge: Why Static Automation is No Longer Enough

In the industrial heartlands of Jubail and Yanbu, the environment is as unforgiving as the global market is competitive. For decades, Saudi plants relied on traditional robotics—rigid, pre-programmed arms performing repetitive tasks in isolation. However, the combination of extreme ambient temperatures, fine desert dust, and the urgent push for non-oil GDP growth has exposed the limitations of "dumb" automation. When a hydraulic seal fails due to heat or a production line bottlenecks in Dammam Second Industrial City, a disconnected robot is simply a heavy liability.

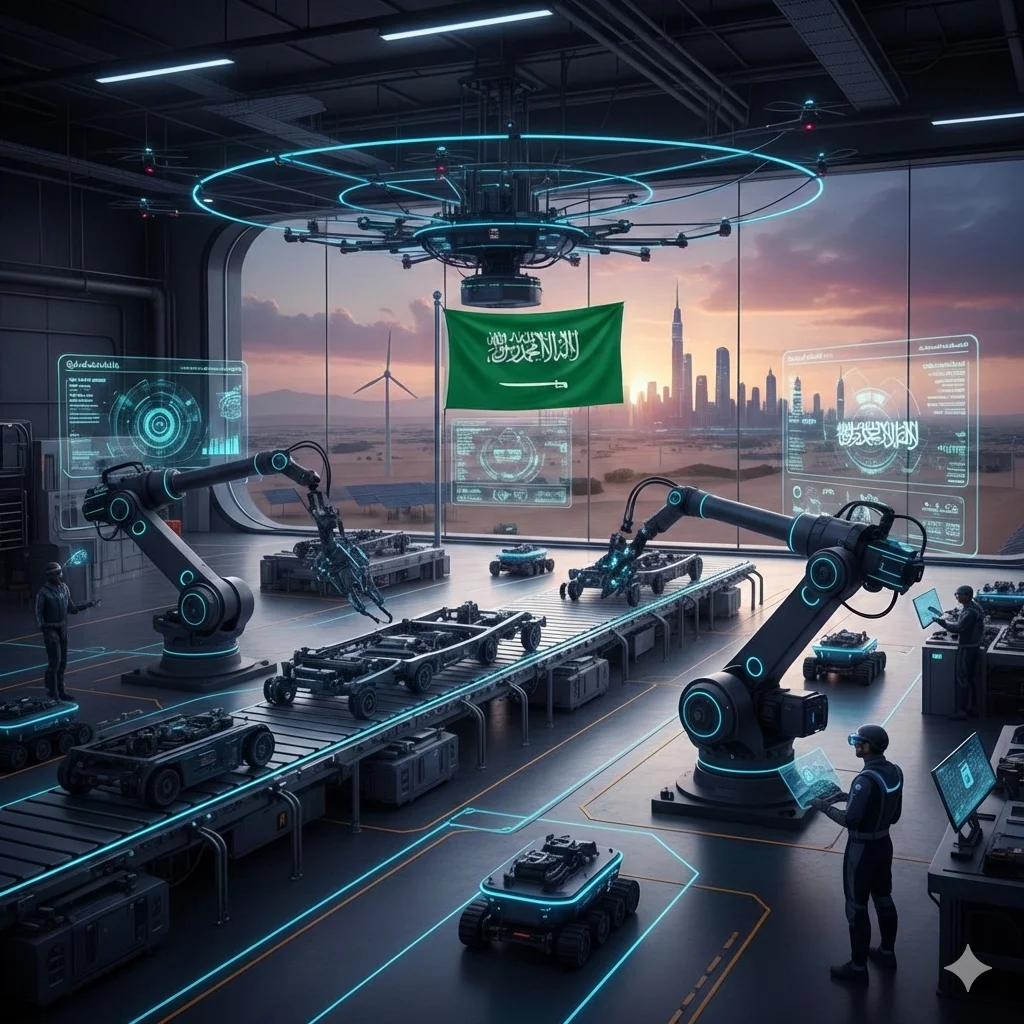

The solution lies in the convergence of robotics and the Industrial Internet of Things (IIoT). By embedding intelligence and connectivity into robotic systems, Saudi industries are moving beyond simple automation toward true autonomous operations. This shift is not just a technical upgrade. It is a strategic mandate supported by the Saudi Vision 2030 and the National Industrial Development and Logistics Program (NIDLP).

As we look toward the future of the Saudi industrial landscape, the goal is no longer just to replace manual labor but to create a self-optimizing ecosystem. This requires a fundamental shift in how we perceive the robot. It is no longer a machine that follows a script. It is a data-generating asset that communicates its health, its environment, and its efficiency in real-time to the plant manager's dashboard.

The Economic Imperative for Connected Robotics

The push for Smart Factory Saudi Arabia initiatives is driven by more than just a love for technology. It is a matter of ROI (Return on Investment) and operational survival. In a global economy, Saudi manufacturers must find ways to lower the cost per unit while maintaining world-class quality. Traditional robotics helped with speed, but they were blind to their own inefficiencies. A robot that operates at 90% efficiency but experiences unplanned downtime twice a month is less valuable than one that operates at 80% with zero unplanned outages.

By integrating IIoT, we enable Predictive Maintenance. For a petrochemical plant in Jubail, knowing that a robotic actuator is vibrating outside of its normal frequency range allows for a scheduled repair during a planned shutdown. This prevents a million-riyal loss that would occur if the line stopped unexpectedly during a peak production cycle. Furthermore, this transition supports the "Human-Robot Collaboration" model, where the Saudi workforce is upskilled from manual assembly to high-level systems management and Digital Transformation oversight.

Technical Deep Dive: The Architecture of a Connected Robot

A modern industrial robot does not treat the robot as a standalone tool. Instead, the robot acts as both an actuator and a sophisticated IIoT edge node. The technical stack typically follows a multi-layered approach that bridges the gap between the physical floor and the digital twin.

1. Sensing and Data Acquisition

Industrial robots are now equipped with an array of IoT Sensors Riyadh-based engineers are increasingly deploying. These go far beyond basic encoders. We are talking about 6-axis force/torque sensors, 3D LiDAR for spatial awareness, and ultrasonic sensors for material density checks. In the NEOM manufacturing zones, we are seeing the use of MEMS-based vibration sensors that detect microscopic wear in gearboxes long before a human operator could hear the difference.

2. The Connectivity Layer & Protocols

Data must move reliably from the factory floor to the control room. This is where the choice of protocol becomes critical. In a typical Saudi facility, we see a hybrid environment:

- OPC UA (Open Platform Communications Unified Architecture): The backbone for secure, vendor-neutral machine-to-machine communication. It allows a Siemens PLC to talk to a KUKA or ABB robotic arm without custom drivers.

- MQTT (Message Queuing Telemetry Transport): A lightweight publish-subscribe protocol. It is perfect for sending robot telemetry over the vast distances of a facility in Dammam where Wi-Fi might be spotty but LoRaWAN or cellular backhaul is available.

- Modbus TCP/RTU: While older, many legacy systems in MODON industrial cities still use Modbus. Modern Industrial Gateways act as translators, converting these legacy bits into high-level JSON objects for the cloud.

3. Edge AI and Processing

Rather than sending every gigabyte of video feed to a central server, Edge AI gateways—often powered by hardware like the Raspberry Pi Compute Module 4 or industrial-grade ESP32 controllers—process data locally. This allows for real-time adjustments. If a vision sensor detects a defect in a molded part, the robot can reject the part in milliseconds. This local "intelligence" reduces latency and significantly lowers data transmission costs.

Advanced Analytics: OEE and the Power of Time-Series Databases

Once the data is harvested from the robot, it must be stored and analyzed. We utilize Time-Series Databases (like InfluxDB or TimescaleDB) because industrial data is inherently temporal. Every sensor reading is a timestamped event. By analyzing these streams, we can calculate OEE (Overall Equipment Effectiveness) with pinpoint accuracy. Plant managers in Khobar can now see not just that a robot is "on," but specifically how its performance fluctuates during the hottest hours of the day, allowing for strategic cooling interventions.

Local Saudi Case Study: Smart Logistics in Al-Qassim

Let us look at a realistic scenario: A large-scale automated date processing and packaging plant in Al-Qassim. Traditionally, this was a labor-intensive process with significant seasonal spikes. The plant transitioned to an IIoT-driven robotic model to handle the Vision 2030 export targets.

The facility deployed a fleet of Autonomous Mobile Robots (AMRs) and robotic sorting arms. The arms use Edge AI to sort dates by grade, size, and moisture content at a rate no human could match. Meanwhile, the AMRs navigate the warehouse using SLAM (Simultaneous Localization and Mapping). These robots are connected via a private 5G network, ensuring low-latency communication with the central SCADA system. When a sorting arm experiences a torque spike—indicating a mechanical jam—it automatically signals the AMRs to reroute to a different packing station, ensuring the line never stops. This integration reduced operational costs by 22% in the first year alone.

Overcoming the "Saudi Constraints": A Senior Engineer's Perspective

Implementing robotics in the Kingdom is not as simple as unboxing a machine. It comes with unique hurdles that require local expertise:

- Extreme Thermal Management: Most industrial robots are rated for 40°C. In Riyadh, warehouse temperatures can exceed this. We mitigate this by using specialized cooling jackets and ensuring our Industrial Gateways are rated for -40°C to +85°C.

- Legacy Machine Integration: Many facilities in Dammam Second Industrial City have machines that are 20 years old. Bridging these "dark assets" to a modern MQTT broker requires a deep understanding of fieldbus protocols and custom hardware integration.

- Cybersecurity and Sovereignty: Adhering to SDAIA and National Cybersecurity Authority (NCA) guidelines is non-negotiable. Data must be encrypted at the edge, and sensitive operational telemetry often must stay on-prem or within a domestic cloud like STC or Mobily.

- The Talent Gap: There is a massive demand for engineers who understand both robotics (OT) and cloud computing (IT). This is why IIoT-Bay focuses on providing platforms that are powerful yet accessible to the local workforce.

Conclusion: The Practical Path Forward

The marriage of robotics and IIoT is the engine of the Fourth Industrial Revolution in the Middle East. For plant managers and stakeholders, the transition from "automated" to "connected" is the only way to ensure long-term resilience. As the Kingdom accelerates its Industrial Digital Transformation KSA, the winners will be those who treat their robotic fleet as a source of intelligence, not just a source of labor. The technology is here, the vision is clear, and the infrastructure is ready.

Is your facility ready for the next level of Smart Factory integration? At IIoT-Bay, we specialize in bridging the gap between legacy hardware and modern autonomous systems. Whether you are looking for IoT Sensors in Riyadh, robust Industrial Gateways, or a complete digital twin of your production line, our Saudi-based team is ready to deliver.

Book a Technical Consultation with our Engineers OR Explore our IIoT Hardware Catalog